TIMELINE ENGINEERING

It has never been easier to combine construction, purchasing and project management.

Especially for individual and project manufacturers

With our new functions, which have been specially developed for individual and project manufacturers, you have the possibility to merge CAD environments and drawing data with the ERP system and fully exploit the advantages of an integrated ERP system.

Always keep track of your drawings, projects, capacities or inventories and benefit from a cross-departmental command center that saves you valuable time.

Every manufacturing industry has its own special processes and requirements for enterprise software. Many ERP systems on the market now offer a wide range of functions and integrations for the most diverse business areas. But if you want to achieve the highest possible efficiency for your own company, there is no way around industry-specific systems.

After 30 years of experience, we know what challenges foundries face and how a software solution can provide the best possible support.

Then take the opportunity of a free online presentation with our sales team.

TimeLine ERP offers foundries a unique basis for more efficient work through industry-specific functions in combination with a broad base of standard modules and complements this with unprecedented adaptability to individual requirements.

Integrated project management with milestones and tasks

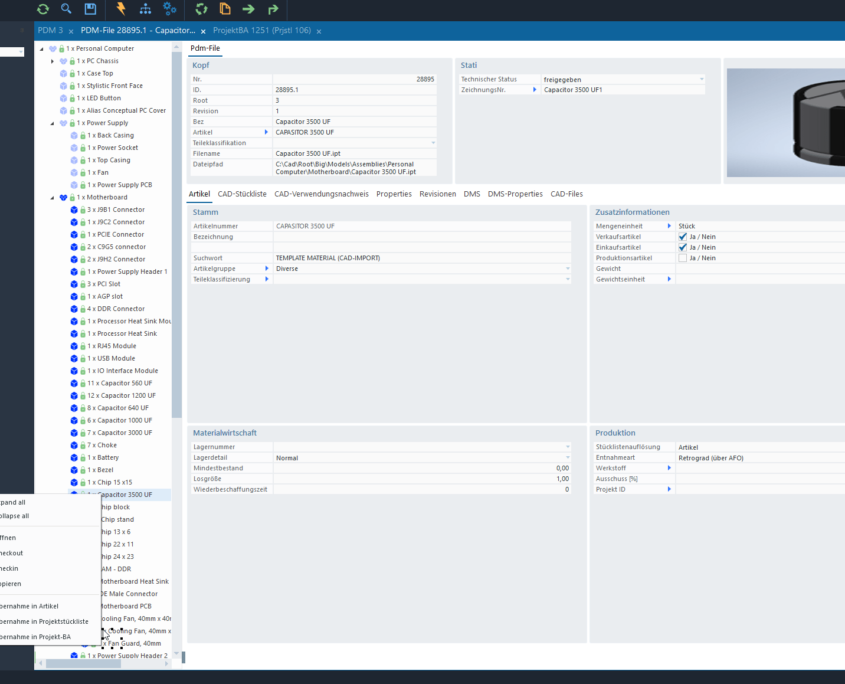

CAD integration with Inventor plugin and PDM

PDM system for CAD data management in the ERP system

Production planning with automated and detailed planning

Product configuration with integrated variant generator

Projects accompany the daily routine of many companies. In order to complete them to satisfaction and on the agreed date, project-related processes and information have to be planned, managed and controlled. The project management in TimeLine bundles all important information of a project in one place. A well designed user interface shows the project in its entirety. Despite high informations density, all key data in the production plan is accessible at a glance: This includes information about upcoming tasks, set milestones, planned costs as well as statements about the project status, personnel or deadlines. For example, you can quickly and easily view bills of materials or material requirements for production orders. In addition, project notes can be created in which you document telephone calls with the customer, e-mails or even visits.

Project management in TimeLine was specificly designed for single-item production and mechanical engineering as well as for the start-up of new parts at series manufacturers. Because of a project beeing ultimately the summary of all tasks, documents and objects that belong to a process, the integration of all processes in the ERP system plays a major role. The project management clearly visualizes all receipts, drawings and documents of a project in a project explorer.

In a project, you bundle all purchasing, sales and production documents into one coherent process and get an overview of all milestones and project phases with a single click. With the milestone control, you can check at any time whether the project is still on schedule.

One of the biggest hurdles in many system architectures is the transfer of CAD designs over to article lists and bills of materials, including all technical characteristics, which can then be further processed in the ERP system. With version 15, TimeLine offers a solution specially developed for individual and project manufacturers that seamlessly integrates the CAD environment into the ERP system, thus efficiently merging CAD and ERP. Thanks to the deep CAD integration, designers can conveniently handle all data and parts lists in the development environment – quite simply via CAD plug-in.

TimeLine reads parts lists and metadata natively from 3D models whilst synchroning them bidirectionally and automatically between CAD and ERP systems. This means that design nodes can be automatically transferred to TimeLine as articles, including the underlying parts lists, and remain synchronized with regard to technical data and revisions (drawing status/drawing index) even after creation.

Transfer design nodes to articles with just a few clicks

Import of the construction incl. all nodes and the corresponding parts list

The revision level is included in all transaction data in the ERP process. If this is changed during check-in or CAD data import compared to the existing status in TimeLine ERP, TimeLine automatically creates an article and a PDM file revision. This ensures audit-compliant administration of inventories, spare parts supply and warehouse management.

When importing PDM files, technical properties are read out and imported into TimeLine. A mapper allows formula-based mappings, which ensure that the available metadata of the 3D models are precisely assigned to the TimeLine article master fields or characteristic bars. IntelliSense supports the simplified creation of syntax-compliant formulas.

Thanks to the possibility of individual mappings, nothing stands in the way of the extensive transfer of supplier articles and standard part data into the ERP system. It would even be possible to import entire catalogs into TimeLine. Since the data import does not automatically generate articles, you do not run the risk of unnecessarily filling up your database.

TimeLine supports native visualization of 3D neutral formats (step and iges) without the need for a CAD viewer or CAD license.

The plug-in for Autodesk Inventor allows you to work with TimeLine directly from the CAD program. Designers can edit all master data from their familiar design environment without having to start TimeLine. The plug-in displays the entire structure tree of the project BOM from TimeLine (in which each node in turn represents a PDM file) and allows direct operations in TimeLine without having to leave Inventor.

TimeLine comes with an integrated PDM system for Inventor, Solid Edge and SolidWorks – but can also be connected to external PDM systems. The audit-proof DMS system manages drawing data in conjunction with the drawing management system. Data can be checked in and out directly via the CAD plug-in, so that the designer does not have to leave his development environment.

Taking into account individual working methods, TimeLine PDM can be operated in two management modes, which differ in the type of drawing management. You can decide whether the workflow of the CAD designers should be maintained or whether TimeLine should take over the physical data management. In this case, you benefit from the audit-proof DMS system and the more extensive integration of the CAD data including all dependencies in the further processes.

Planning is the heart of every production operation – and the weak point of most ERP systems. Where other systems run out of steam, the functional diversity of TimeLine’s production module really begins.

Project BOMs are single-level or multi-level parts lists that can be created directly via CAD import. Project BOMs can contain new parts or existing articles. For new parts, it is possible to create the article master directly from the project parts list. In this case, the sub-articles and the parts list of the selected assembly are also created automatically.

With the BOM comparison growing BOMs can be mapped. New parts, deleted parts and modified parts are displayed between any two BOMs with the option to manually adjust the existing BOM or overwrite it with the new BOM. Linked purchase orders and other linked documents are linked to the new BOM items.

As an intermediate piece between the PDM structure and the project operation order, the project BOM thus allows the revision of the entire BOM structure and is a prerequisite for the BOM update (growing BOM).

Here, a preliminary bill of materials can be transferred to a project operation order so that production can begin even though the design has not yet been completed.

The Project Operating Orders supports assembly-related release, which allows selective disposition (and ordering) of only the parts released by the design. With advanced design, a new version of the project BOM can now be created in the CAD system. Since Inventor and other CAD systems do not generate unique BOM items, TimeLine PDM takes over this function.

For the Project Operating Order, it does not matter whether an assembly or BOM item has a TimeLine article number or not. Particularly in the case of cut-to-size items that occur once, the assignment of article numbers is very obstructive, so in TimeLine they can be dispensed with entirely. Price inquiries, purchase orders and even sub-operation orders can be produced “article-less”.

Laser, nesting and cutting lists in a few simple steps.

Work sequences can be attached to any assembly node of a Project Operating Order. These result in a multi-level work plan, which can be planned e.g. in forward scheduling BottomUp – in backward scheduling TopDown – here the usual PERTT link is mapped via the project BOM. However, if this is too time-consuming, so-called “Pool AFOs” can be used to manage flat-rate operations without assembly assignment in the Project BOM, which nevertheless enable a preliminary, final costing and planning of the Project BOM – without the need for a dedicated routing. These pool routings can also be copied from templates – a further simplification.

Variant manufacturers are technologically divided into two groups:

TimeLine maps both the constructive variant generation through the integrated PDM in connection with the “SmartCopy” function, as well as the configurator-supported variant generation via an integrated variant generator.

The Inventor plug-in from TimeLine has a so-called “SmartCopy” function. This allows TimeLine PDM to directly intervene in the assembly references of the target CAD system to exchange assemblies and parts or to redefine them by means of a similarity copy.

TimeLine selectively replaces the variant-forming parts in the CAD files with new parts (by changing the assembly references).

For users where variant creation takes place in the ERP system rather than in CAD, TimeLine contains a formula- and characteristic-based variant generator that allows product configuration via technical characteristics.

The configuration is carried out via a variant template: a multi-level maximum bill of materials of any depth, which is reconfigured by selecting the characteristics.

Then simply arrange a free online presentation

with our sales team